- What conditions are necessary for life?

- Does life exist outside of the solar system?

- How do stars and planets form and evolve?

- What is the universe made of?

- Planetary Geology

- Solar and Stellar Atmospheres

- Space Weather

- Medical Applications

- Machine Learning

- Atomic & Molecular Data

- Cosmic Microwave Background

- Gravitational Waves

- Cosmology

- Einstein's Theory of Gravitation

- Extragalactic Astronomy

- Instrumentation

- Planetary Systems

- Stellar Astronomy

- The Energetic Universe

- The Milky Way Galaxy

The CfA is collaborating with a number of institutions around the world to create the Giant Magellan Telescope (GMT), currently under construction in Chile.

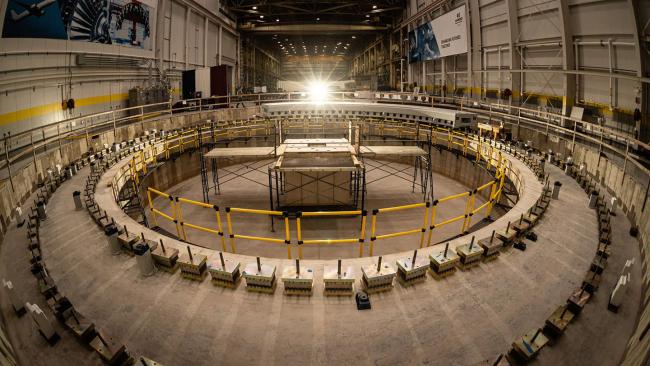

Manufacturing and assembly of the largest telescope mount built in the United States has begun. In partnership with Ingersoll Machine Tools and OHB Digital Connect, fabrication of the 39-meter-tall precision moving structure is taking place across multiple states over the next six years. When complete, the mount will be shipped to the Giant Magellan Telescope site in Chile for reassembly. Credit: Giant Magellan Telescope

The Giant Magellan Telescope (GMT) and Ingersoll Machine Tools Inc. have announced the start of manufacturing and assembly of the largest telescope mount built in the United States. The 39-meter-tall precision moving structure was developed in partnership with OHB Digital Connect. Once assembled, the mount will undergo performance testing before being shipped nearly 6,000 miles to the Giant Magellan Telescope site in Chile for reassembly.

The Center for Astrophysics | Harvard & Smithsonian (CfA) is one of the founding institutions behind the GMT. Both of the CfA's partner organizations – the Smithsonian Astrophysical Observatory and the Harvard College Observatory – are contributing to the development, construction, and instrumentation for the GMT.

The Giant Magellan Telescope mount weighs 2,100 metric tons and is designed to support seven of the world’s largest mirrors, adaptive optics, and scientific instruments. Despite its immense size, the mount is remarkably agile, gliding frictionlessly on a film of oil just 50 microns thick, resisting image quality disruptions and allowing it to track celestial objects billions of light years away. The steel structure sits atop a 22-meter-diameter concrete pier that was engineered to protect the telescope during seismic events in the Chilean Atacama Desert.

The Giant Magellan Telescope will be 200 times more powerful than today's best telescopes. This power stems not just from its large 25.4-meter diameter primary mirror array, but also from the synergistic performance of its efficient optical design and advanced scientific instruments. The innovative design makes the Giant Magellan Telescope unique among the new class of "extremely large telescopes" for its ability to deliver the highest performing combination of image quality, field of view, and light sensitivity ever achieved.

"Our cost-effective design enables us to build the Giant Magellan Telescope faster and with less risk, all while achieving the broadest range of scientific capabilities," said Robert Shelton, President of the Giant Magellan Telescope. "Ingersoll's global experience in manufacturing giant precision structures has been instrumental on our way to becoming one of the most powerful ground-based telescopes in the world."

Advancement of mount fabrication marks a major milestone for the Giant Magellan Telescope, now 40% under construction across 36 states and on track to be operational in Chile by the early 2030s.

For more information on the CfA and GMT, visit https://www.cfa.harvard.edu/facilities-technology/telescopes-instruments/giant-magellan-telescope.

[This text was modified from a press release issued by the Giant Magellan Telescope on August 28, 2024.]